16th Century

Our story begins way, way back in the 1500s where we first see instances of society producing their own sealants – in the broadest sense – as a means of building. Far from ideal, everything from plant resin and mud to blood and beaten eggs were used to seal up houses from the bad weather at this time.

In the late 1590s, it’s even reported that famed explorer and writer Sir Walter Raleigh used natural calk from the ground in Trinidad to seal up and repair his ship during long journeys to and from the Americas.

17th Century

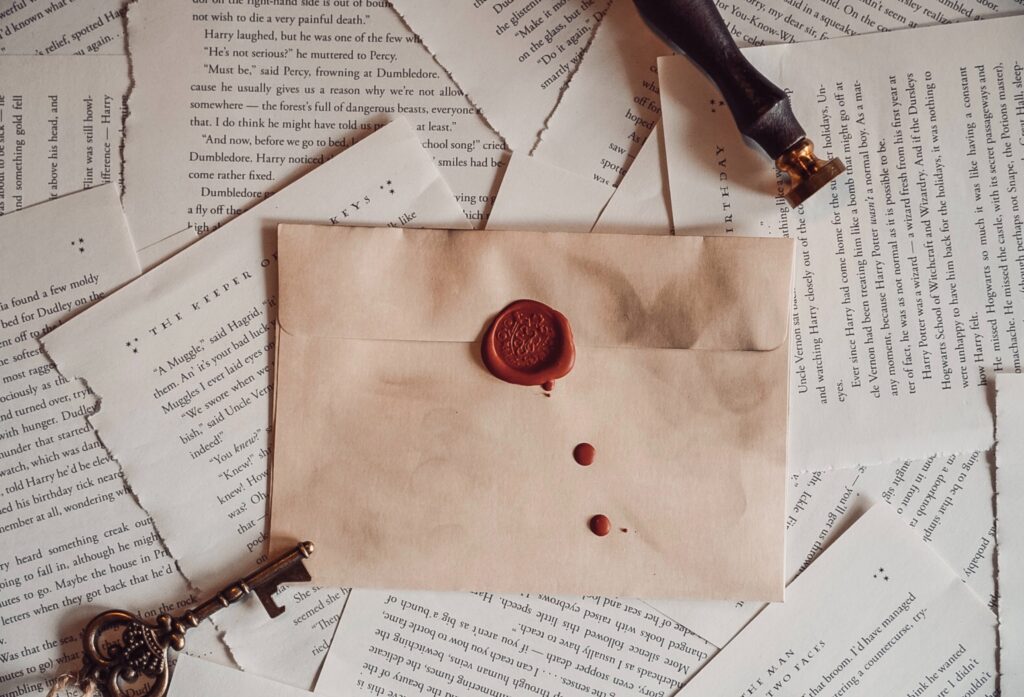

Keen to copy the success of Native America, which used amber as a means of filling gaps and weatherproofing, Europeans developed sealing wax as a readily available alternative. Although originally intended for sealing letters and food containers, sealing wax was eventually used for all kinds of repairs and ultimately proved most useful during the rise of modern plumbing, where cracks and joints needed regular filling.

19th Century

As we know, sealing wax becomes soft and malleable under high temperatures, which meant that hot summer days caused some significant problems in the industrial world, particularly with plumbing.

Thankfully, in comes John Dicks, heir to a sealing wax business, who through a period of trial and error produces the first long-lasting caulk that wouldn’t be altered by the heat – at long last!

1920s

In the early half of the 20th Century we start to see more sophisticated, chemical-based sealants being developed for construction. In the 1920s polymers such as acrylic and butyl polymers were discovered for their weather-proofing qualities and here we begin to see the seeds of the sealants industry as we know it today.

1950s – 70s

By the early 50s, homeowners and sole-traders could start to buy individual pots of John Dicks’ revolutionary caulk and its popularity was growing, but large-scale construction contractors needed something even better.

While caulk hardened quickly and lacked malleability, acrylic and latex-based sealants offered something much more flexible that wouldn’t dry out. In 1964, commercial companies took up widespread use of latex polymers and by the late 60s synthetic-polymer-based sealants were the new norm.

1980s

A few short years later, silicone sealants – still the most popular type today – are invented. Silicone products were designed to cure quickly and form a strong, flexible and watertight seal that does not shrink. They fast became the favoured option for interior and exterior surfaces and were rolled out to handymen and construction companies worldwide.

1990s

Useful alternatives start to emerge off the back of the silicone industry, including expanding latex foam to fill large cracks and heavy duty Polyurethane sealants for exterior protection.

2000s

The 21st Century has seen widespread developments in the safety and environment-impact of sealant products. Modern inventions have included fire-stopping sealants designed to impede the spread of flames and smoke between rooms, as well as food hygiene polymers used for commercial kitchens and food preparation areas.

In recent years we’ve also seen a very necessary demand for sealant and adhesives specifically designed for aerospace engineering. Everything from fuel tanks to aircraft windshields need to be sealed securely and incredibly safely, and so high-strength silicone sealants have been developed for the safety of military, commercial and private air travel.

From the humble beginnings of mud and egg mixtures to complex chemical compounds designed for aerospace travel, the sealant industry has come a long way over the centuries.

Hugely important to modern life, there’s no doubt that we’ll see even more progress when it comes to sealant products in the years to come.